WHS: Hierarchy of Control Measures

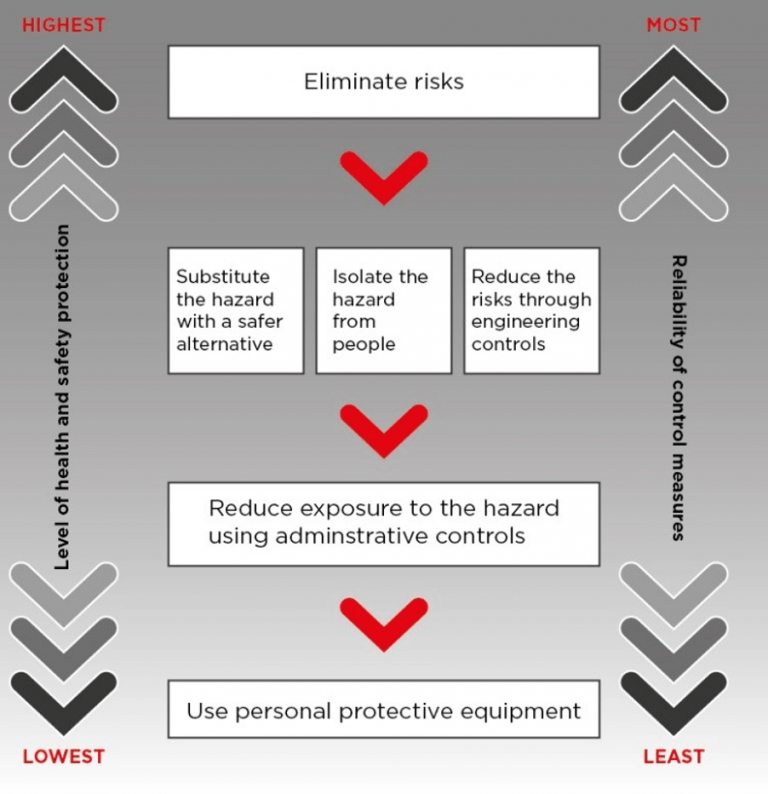

When it comes to any risk – Work Health & Safety (WHS) Regulations make it mandatory for employers to work through a hierarchy from the highest level of protection and reliability to the lowest.

What are the WHS hierarchy of control measures?

Level 1: Elimination

Elimination is the most effective control measure as it eliminates both the hazard and associated risk.

This control is easiest to achieve at the design/ planning phase and is often the cheapest.

During the early stages, there is greater scope to incorporate control measures and identify unnecessary hazards e.g. not using a noisy machine is better than providing personal hearing protectors.

As it may not be reasonably practicable to eliminate hazards, then as an employer, it is your duty of care to minimise as many risks associated with hazards as reasonably practicable.

Level 2: Substitution, Isolation & Engineering Controls

Level 2 of the hierarchy is to use one of the following approaches:

Substitute the hazard with something safer:

To be an effective control, the substitution must not produce another hazard e.g. replaced lead-based paint with titanium white. This control can be grouped with elimination because, in effect, the first hazard is removed from the workplace.

Isolate the hazard from people:

This control involves separating the hazard from people by using barriers or distance. For example, using remote controls to operate machinery, store chemicals in a fume cabinet, barriers between workers and customers where there is a risk of virus contamination or assault.

Use engineering controls|

Engineering controls are physical in nature, including a process or a mechanical device.

E.g. trolleys to carry heavier loads, setting work rates on the production lines to reduce fatigue and installing electrical safety switches.

Level 3: Administrative Controls

At level 3, the risks remain but must be minimised by implementing administrative controls.

This includes implementing work procedures that are designed to minimise exposure to hazards and providing relevant information, training and instruction to ensure workers can work safely.

E.g. develop procedures for how to operate machinery safely, implement anti-bullying policies, use effective signs to warn people of surrounding hazards.

Some administrative measures are necessary to ensure level 2: substitution, isolation and engineering controls are implemented effectively.

For instance, following instructions when using the equipment.

Level 4: PPE

At level 4, PPE is considered the least effective as they do not control the hazard at the source and instead rely on human behaviour and supervision.

This control measure should be only used as a backup, a short term interim measure until a more effective way can be used, or where are no other practical control measures available (as a last resort).

WHS outlines that if PPE is to be used, you must ensure:

- Equipment is suitable for the nature of work and that PPE is of suitable size and fit reasonably comfortable for workers to wear

- Equipment is maintained, repaired, clean, hygienic and in good working order to ensure it continues to minimise risk to the worker who uses it

- Training and instruction in the proper use of wearing PPE

- Storage maintenance of PPE

Read more @ Safe Work Australia

As always, should you need some help, please get in touch.